In today’s rapidly evolving industrial landscape, procuring the right components to keep operations running smoothly is more critical than ever. Many industry professionals now shop industrial screws and fasteners online to meet tight deadlines, reduce procurement costs, and access an expansive selection of products. Online inventory platforms provide users instant access to technical specifications, peer reviews, and expert guidance, making informed purchasing a possibility and a reality.

Shopping online transforms traditional procurement by widening the range of product choices and streamlining the sourcing process. Industrial suppliers on the web often feature advanced filtering tools, downloadable datasheets, and direct links to compliance documentation, ensuring that engineers and purchasing managers can make decisions transparently. The ease of virtual shopping continues to boost industry efficiency, with research from Forbes underscoring the pivotal role of technology in transforming modern supply chains.

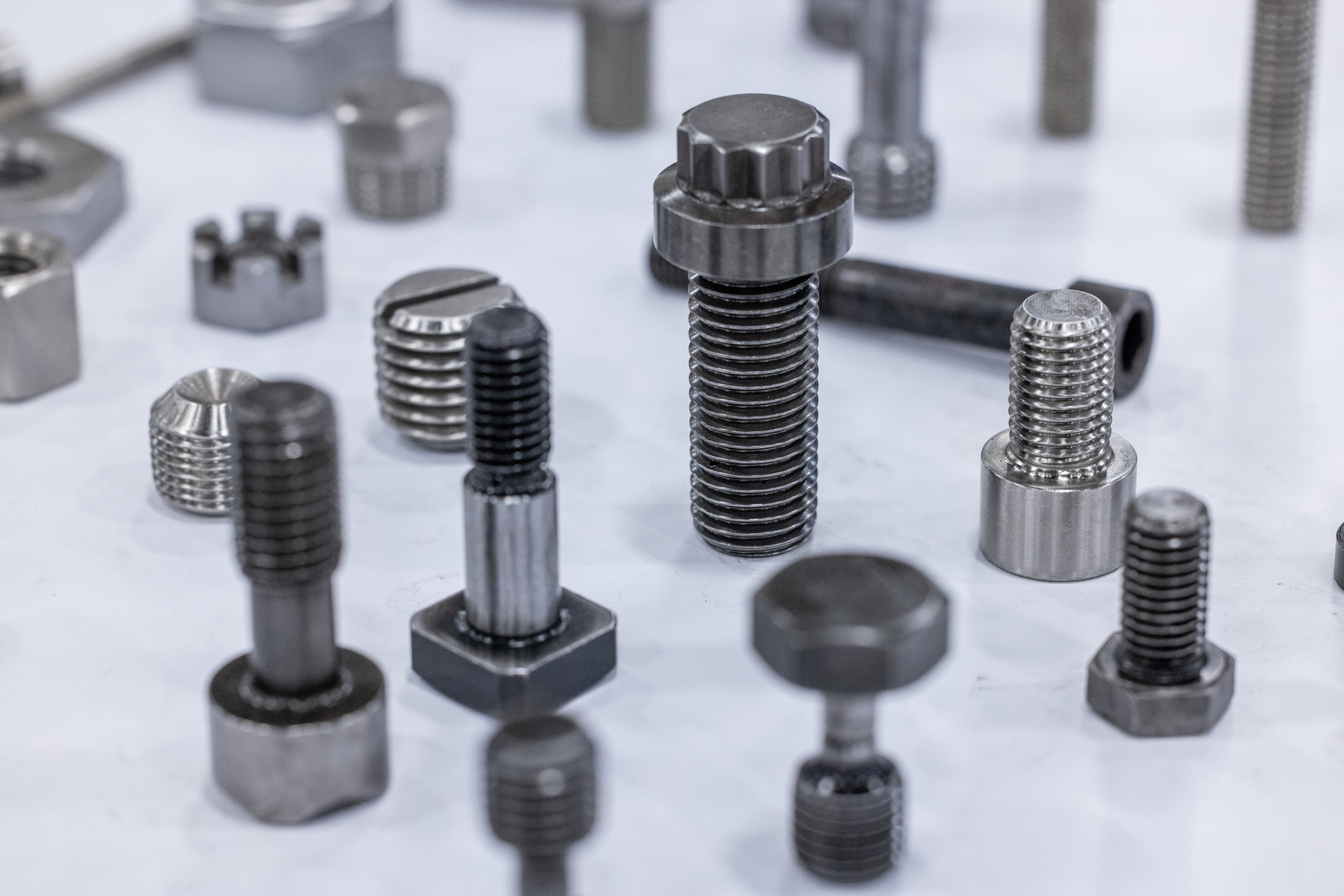

How to Choose the Right Fastener for Your Project

The foundation of any successful project is the proper selection of fasteners. Start by thoroughly assessing the nature of your application—considering variables such as environmental exposure, load demands, required strength, and potential for corrosion. Key attributes like thread pitch, head style, and driver engagement will also influence your decision. According to Engineering.com, failing to match fastener types to project requirements can lead to premature failures, increased maintenance costs, and even safety risks.

This is why detailed planning and careful evaluation of specifications are so crucial at the earliest stage. Working with suppliers that provide detailed product data and expert service can help you navigate various industrial fastener types and avoid costly errors.

Materials Matter: Understanding Your Options

- Steel: Widely used due to its range of strengths and cost-effectiveness. Carbon and alloy steels suit various industrial uses based on their durability and tensile strength.

- Stainless Steel is vital in marine, medical, and outdoor environments because it is known for exceptional corrosion resistance and long-lasting performance.

- Brass and bronze: These alloys are ideal for electrical and plumbing applications due to their conductivity and resistance to corrosion by certain chemicals.

- Alloy Metals: Specialty alloys are often specified for high-stress, high-precision, or extreme temperature applications where standard materials may fail.

Material selection will directly influence your project’s lifespan, safety, and total cost of ownership. Always double-check grade markings, and don’t hesitate to request material certifications from your supplier before confirming a bulk order.

[suggestion]A simple image showing assorted industrial screws and fasteners arranged neatly on a clean surface, with a few material labels (such as steel, stainless steel, brass) below each group.[/suggestion]

Quality Assurance and Certification: What to Look For

Quality assurance in industrial fasteners cannot be overstated. Always choose components backed by established certifications from organizations such as ASTM, ISO, or DIN. These benchmarks prove that the fastener has passed rigorous testing for strength, performance, and safety. Reputable suppliers provide certificates and keep up-to-date product datasheets accessible. Documentation is essential in regulated industries, ensuring compliance and minimizing liability.

Comparing Product Options and Prices

The digital nature of online fastener shopping gives you unique product and price comparison tools. To ensure optimal value:

- Create a clear list of your fastener requirements—dimensions, thread types, head shapes, and finishes.

- Use platform filters to narrow options based on technical needs.

- Read up-to-date customer reviews for insights into performance and supplier reliability.

- Factor in logistics—shipping charges, expected delivery timelines, and any minimum order requirements.

Transparent side-by-side comparison helps optimize cost and compatibility, reducing the risk of incompatible purchases and overspending.

The Benefits of Buying in Bulk Online

Bulk ordering of industrial screws and fasteners online offers clear financial and operational rewards. Volume purchasing often qualifies buyers for discounted rates, improving cost efficiency for high-frequency applications. Additionally, bulk orders simplify inventory management, ensuring you have reliable access to essential parts and minimizing unplanned downtime—a vital priority for industries with stringent project schedules and unpredictable demand.

Shipping and Logistics Tips When Shopping Online

Timely delivery is crucial to prevent project delays. Before placing your order, check for express shipping and confirm inventory status—especially for custom, high-value, or specialty orders. Evaluate fulfillment locations to predict lead times accurately, as products shipped internationally or from multiple warehouses can affect logistics. The ability to track shipments in real-time and receive proactive notifications is rapidly becoming a standard, supported by leading online suppliers and recognized by industry experts at The Wall Street Journal.

Future Trends in Online Fastener Supply

Digital procurement is evolving. Expect more innovative online platforms using artificial intelligence for real-time product recommendations, dynamic inventory monitoring, and auto-reordering capabilities. These innovations will minimize shortages, improve forecasting accuracy, and increase user satisfaction. Enhanced analytics and integration with buyer procurement systems are also set to redefine how fasteners are sourced and managed in the coming years.

Helpful Resources for Industrial Procurement

To further expand your knowledge on fastener materials, industry certifications, and procurement strategies, consult prominent standards organizations such as ISO and leading trade publications. Staying informed with trustworthy sources supports safer, more efficient decision-making during every phase of the fastener selection and purchasing process.

Approaching your next purchase with these key strategies will ensure you optimize performance, safety, and cost-effectiveness each time you shop for industrial screws and fasteners online.

Making informed decisions when purchasing industrial screws and fasteners ensures both quality and long-term reliability. By focusing on material strength, application needs, and supplier credibility, buyers can avoid costly setbacks. Careful selection not only supports safety and performance but also contributes to smoother operations and greater efficiency in any project.